Tired of Broken Bandsaw Blades? Read This Before Your Next Cut

Are you tired of constantly replacing broken bandsaw blades?

If your metal bandsaw blade keeps snapping, you are not alone. This is a common issue in many metalworking shops. The good news is: it is preventable.

With the right blade selection, proper setup, and consistent maintenance, you can significantly extend blade life, improve cut quality, and maintain efficient operations. In this article, we explain why bandsaw blades break and share practical tips to help you reduce downtime, save costs, and achieve better cutting performance.

Why Do Metal Bandsaw Blades Keep Snapping?

Before we address the solution, it is important to understand the root causes. Below are the most common reasons metal bandsaw blades fail:

1. Excessive Tension

Applying too much tension does not make the blade stronger; it weakens it. Excessive stress on the blade often results in premature failure.

2. Incorrect Blade for the Material

Different metals require different blade types. Using the wrong tooth pitch or blade design can create uneven pressure and accelerated wear.

3. Blade Fatigue

Over time, blades naturally wear out, especially when they are frequently flexed, overheated, or exposed to high strain. This causes micro-cracks that eventually lead to breakage.

4. Misaligned Guides or Wheels

If the blade guides are not properly aligned or if the wheels are damaged or worn, the blade can twist or drift during cutting, which increases the risk of cracking.

5. Excessive Feed Pressure

Pushing the material too aggressively overloads the blade. It is important to let the blade cut at a steady, controlled rate.

6. Tight Radius Cutting

Making cuts that are too tight for the blade’s width can place excessive strain on the blade, increasing the risk of snapping.

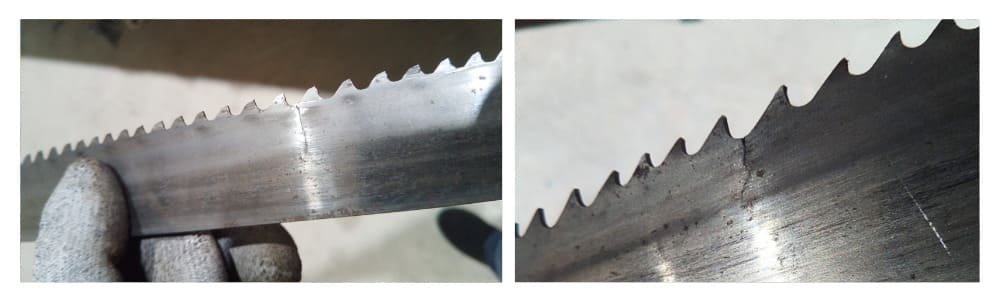

7. Poor Weld Quality

In welded blades, the weld joint is often the weakest point. If the weld is not properly aligned or fused, the blade may break at the seam.

Seven Ways to Prevent Blade Breakage and Extend Blade Life

Now that we have identified the causes, here are seven proven strategies to extend the life of your metal bandsaw blade:

1. Select the Appropriate Blade

Not all bandsaw blades are the same. For optimal performance:

- Use a fine-tooth pitch for thin or hard metals (such as stainless steel or tool steel).

- Use a coarse tooth pitch for thicker or softer metals (such as aluminum or mild steel).

- Match the blade width to the specific type of cut, especially for curves or tight radii.

Choosing the correct blade is critical for maximizing durability and cutting performance.

2. Break In New Blades Correctly

New blades should not be used at full speed immediately. Similar to a new engine, they need a proper break-in period.

Break-in procedure:

- Begin with 50% of your normal feed pressure.

- Cut for 5 to 10 minutes.

- Gradually increase to full pressure.

This simple step can increase blade life by 25 to 30 percent.

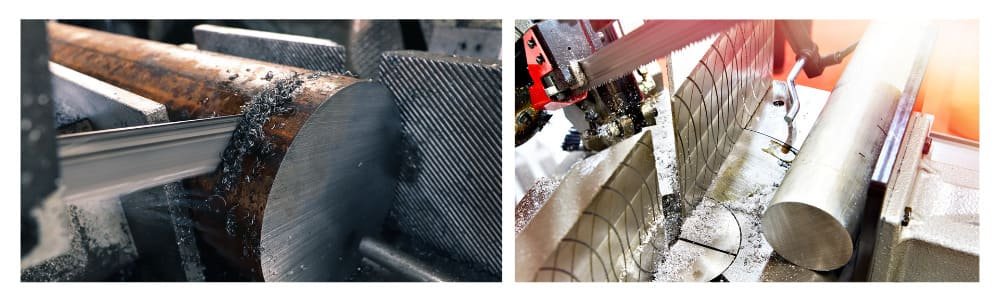

3. Maintain Proper Speed and Feed Rate

Speed and feed settings play a critical role in blade longevity.

- If the metal chips are blue or brown, the blade is overheating.

- If you hear squealing or grinding, the feed rate is likely too high.

Adjust your surface feet per minute (SFPM) and feed pressure according to the material and blade type.

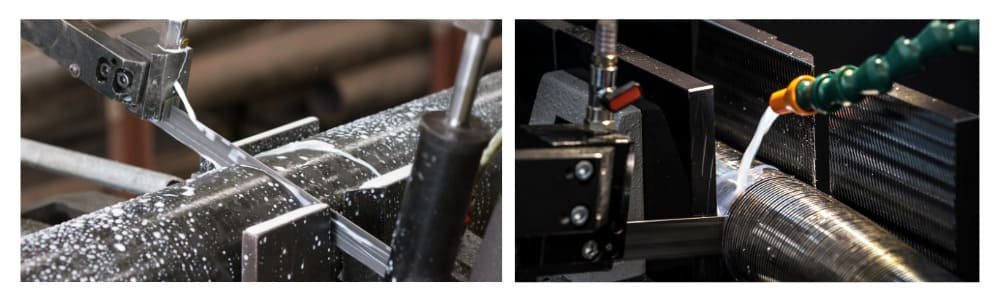

4. Use Coolant and Lubricant Correctly

Heat is one of the main causes of premature blade wear. A proper metal cutting fluid helps cool the blade, reduce friction, and remove chips.

Best practices include:

- Ensuring a consistent flow of coolant to the cutting zone.

- Cleaning the coolant system regularly.

- Avoiding mixtures that are overly diluted, as they reduce lubrication efficiency.

5. Maintain Your Bandsaw Machine

Even the best-quality blade cannot perform well on a poorly maintained machine.

Inspect the following daily:

- Blade tension

- Guide alignment

- Chip brush functionality

- Drive wheel condition

Taking a few minutes for inspection can prevent hours of unplanned downtime.

6. Check and Set Proper Blade Tension

Incorrect tension—either too loose or too tight—can cause poor cuts and accelerated wear. Always follow the manufacturer’s tension specifications.

Recommendation:

If your machine does not have a built-in tension gauge, consider installing one for greater accuracy.

7. Store Blades Properly

Even unused blades can become damaged if stored incorrectly.

Storage guidelines:

- Hang blades on a rack or store them loosely coiled.

- Keep them in a dry, clean area away from moisture and corrosive materials.

- Label different blade types to avoid mix-ups and ensure quick access.

Ready to Optimize Your Bandsaw Setup?

If you are in metalworking, oil & gas, or heavy industrial fabrication, make sure your blades are working as hard as you are.

Need help choosing the right bandsaw blade for your operation? Contact our technical team — we will help you spec the perfect blade for your needs.