Top 5 Signs Your Bandsaw Blade Needs Replacing

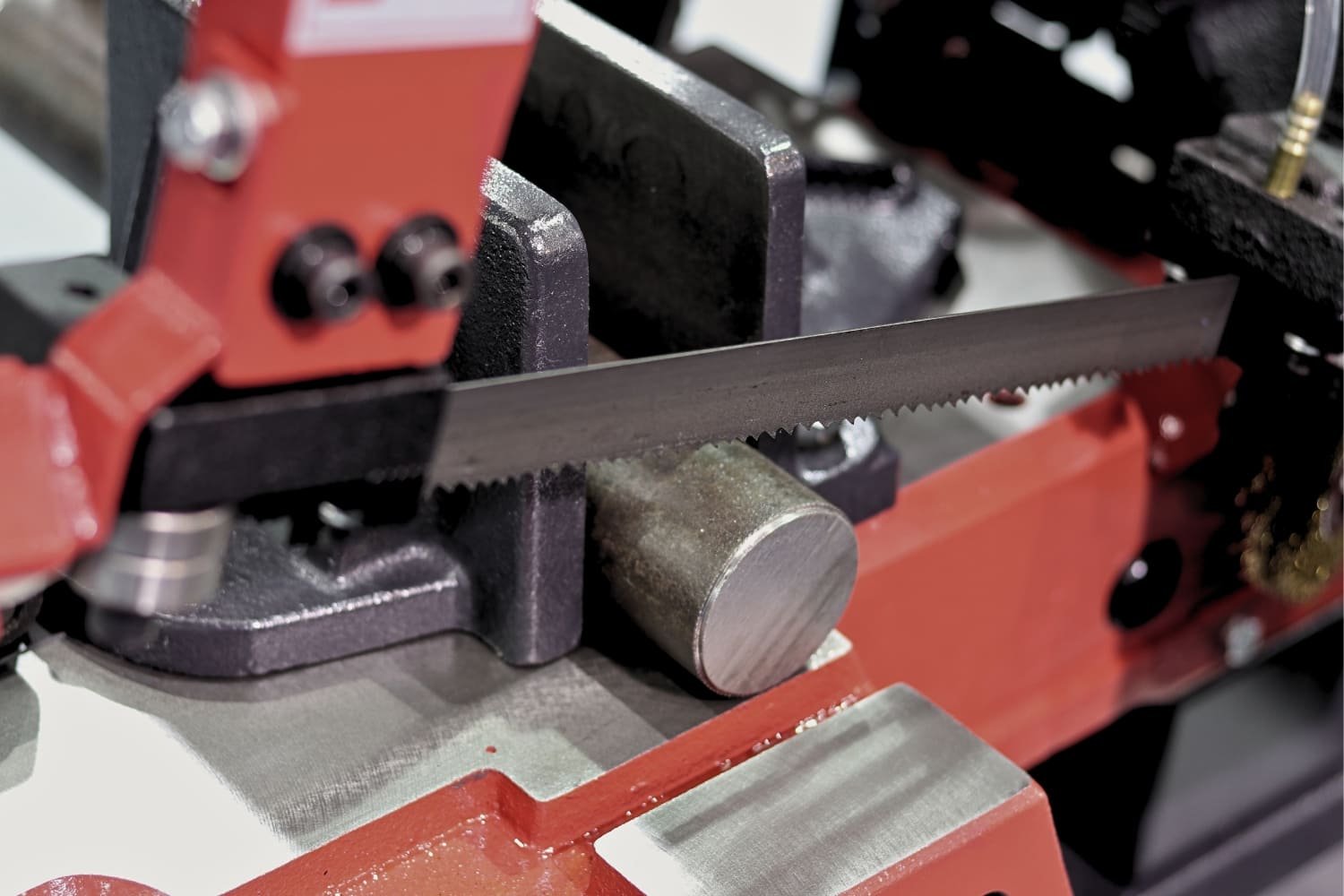

A metal bandsaw blade for metal cutting is a critical component in any metalworking shop. While the bandsaw machine provides the power and control, it is the blade that does the real work. Over time, even the best blades wear down, impacting precision, safety, and productivity. Knowing when to replace your blade is crucial for maintaining cutting quality and protecting your equipment.

Here are the top 5 warning signs that it is time to replace your metal bandsaw blade.

1. Poor or Inconsistent Cutting Performance

One of the first signs that your bandsaw blade is dull or damaged is a noticeable drop in cutting quality:

- Slower cutting speed, even on thin or soft metal.

- Needing to apply extra force to push material through.

- Vibration or unusual noise during the cutting process.

Proper blade installation is crucial, including tension adjustment as per the machine’s guidelines. Low blade tension can cause the blade to wobble, resulting in chips and clogged teeth. Always use a blade tension gauge and adjust according to the machine’s recommendations. A dull blade won’t cut cleanly – it tears through material, resulting in a rough and imprecise cut surface.

2. Inability to Follow a Straight Cut Line

A sharp metal bandsaw blade should track straight and clean through the material. If you notice:

- Cuts that drift or curve away from the guide.

- Frequent need to realign or redo cuts.

- Inconsistent thickness or angled edges.

This is commonly caused by dull teeth that can not cut straight, a bent or uneven blade, or worn-out blade guides. These signs indicate the blade has lost its stability. A worn blade can lead to dimensional inaccuracies and material waste. In industrial processes, even small cutting errors can have serious consequences for final product quality. Replacing the blade restores cutting accuracy and production efficiency.

3. Unusual or Loud Noises During Operation

A healthy bandsaw blade for metal should run smoothly and relatively quietly. Sounds to watch out for include:

- Squeaking, squealing, or rubbing sounds – this may indicate abnormal friction between the blade and the material.

- Loud knocking or metal clanking – this could signal issues with blade tension, misalignment, or the blade’s condition.

These sounds are often caused by worn or dull blades that are being overworked, improper machine settings, or insufficient lubrication. While it’s normal for blades to make some noise during use, increasing or persistent noise levels can be a warning sign that it’s time to replace the blade. Dull or cracked teeth and misaligned installation due to wear can compromise performance. Replacing the blade can restore smooth operation and extend the machine’s lifespan.

4. Burn or Heat Marks on the Metal

When your bandsaw blade for cutting metal leaves burn marks or heat discoloration on the material, it could mean:

- The teeth are too dull, causing excessive friction.

- The feed rate is too fast for the blade to handle.

- The cutting speed or blade pitch is not appropriate for the material.

Excessive friction creates heat, which can result in smoke or a burning smell. If this happens, stop cutting immediately and inspect the blade. Continued use in this condition may damage both the material and the saw.

5. Visible blade damage

Visual inspection is helpful in determining blade condition. Look for the following signs:

- Broken or missing teeth.

- Cracks or fractures on the blade body.

- Bent or twisted blade shape.

- Use beyond the blade’s recommended lifespan.

Such damage significantly reduces cutting performance and poses a safety risk. Even if the blade can still be cut, any physical damage is a red flag that it should be replaced immediately to prevent total failure during use.

Time to Replace That Worn-Out Blade?

Do not let a dull or damaged metal bandsaw blade slow down your workflow or compromise cutting precision. If you are starting to notice the warning signs, it is probably time for a replacement. Whether you are cutting structural steel, pipe, or specialty alloys, the right blade makes all the difference.

Need help finding the ideal metal bandsaw blade for your application? Our technical team is ready to assist. We will help you choose the perfect blade based on your material, machine, and production goals. Contact us today and keep your cuts clean, safe, and efficient.